Co-Design

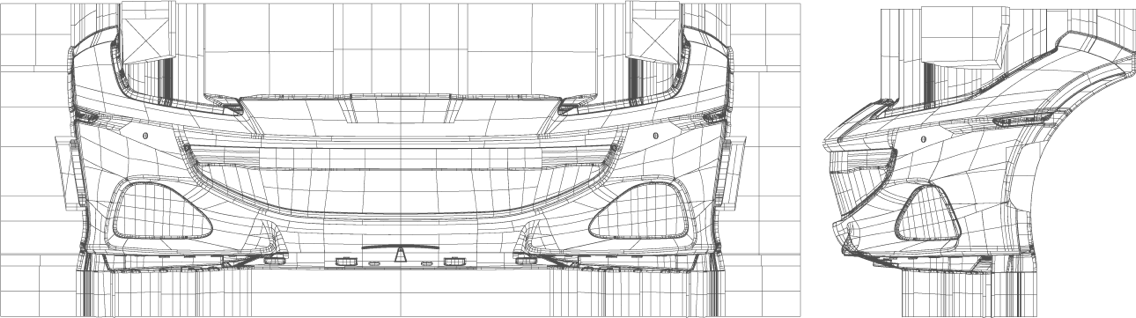

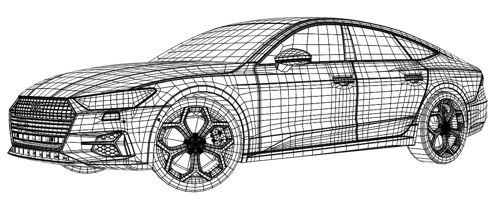

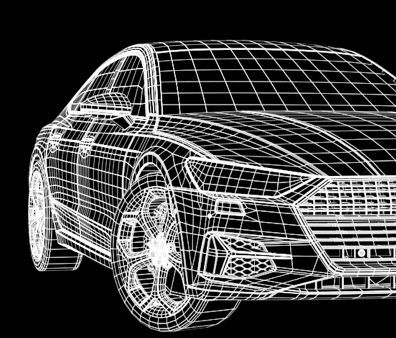

Thanks to the technical competences acquired throughout several years of experience, ENNEGI is able to offer product co-design services.

It is always more and more important to be involved in the product design in order to reduce process problems and improve the aesthetic and quality result of the product itself.

Molds and tools are relevant to reach these targets, so ENNEGI, cooperating in the design phase, helps the Customer to choose, taking its responsibilities.