- Forming and Covering Mold: in aluminum or steel for forming and covering, with integrated blades for trimming the component. Depending on the raw-material used, mold can be heated up (Thermo-set Technology) or cooled down (Thermoforming Technology).

- RRIM Mold: in aluminum or in steel, with necessary mechanical or hydraulic movements to get component feasibility.

- Cooling Shell: in resin or aluminum, with forced cooling system (air or water).

- Gluing Station: in aluminum or resin, with manual or pneumatic system.

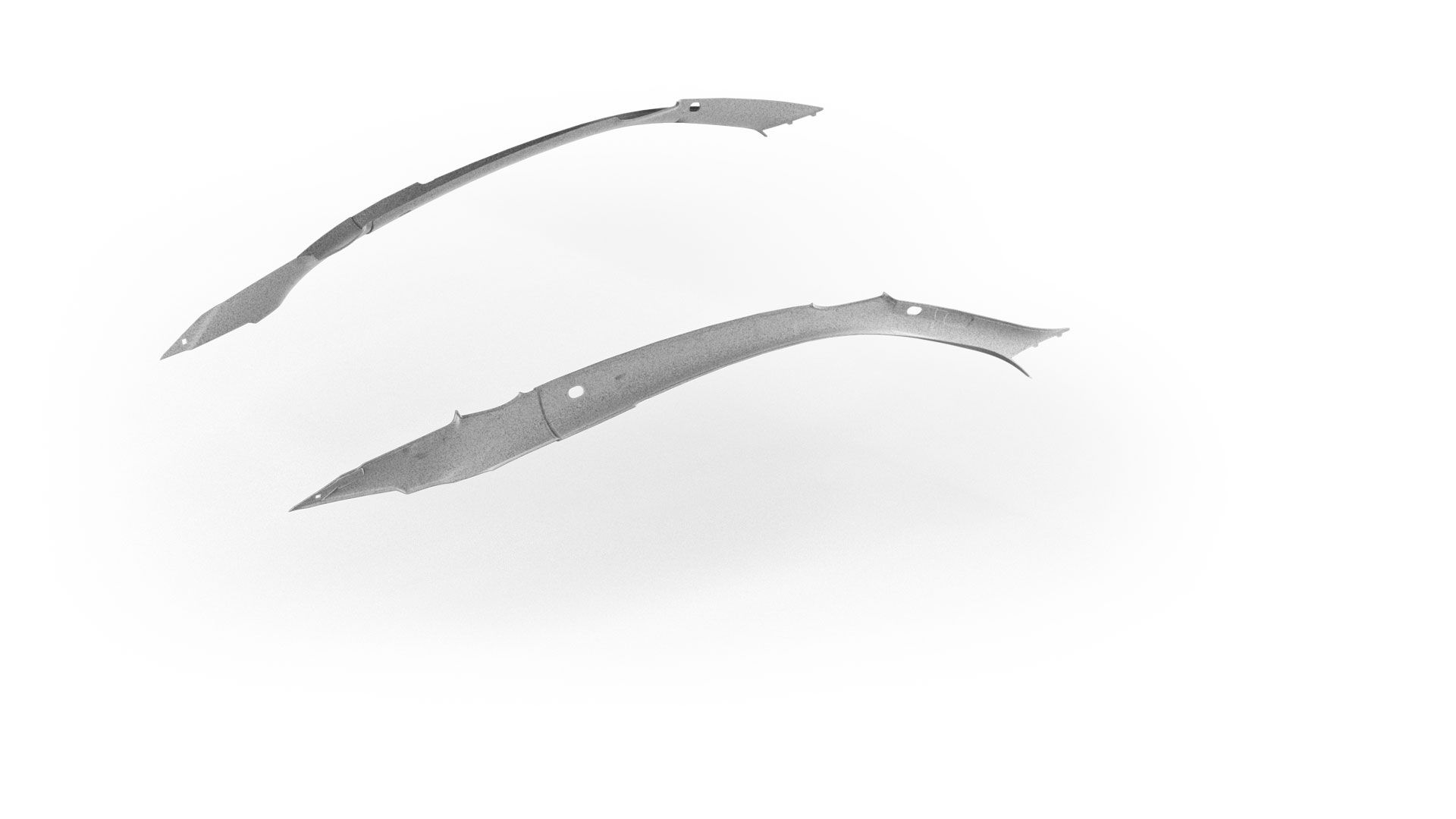

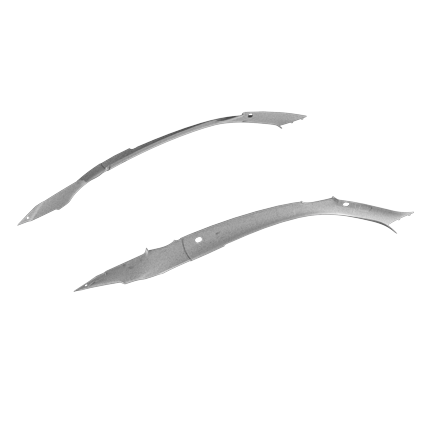

- Trimming Nest: in resin to cut part of the component.

- Checking Fixture: in resin (light) or in aluminum (full) to check dimensionally the component.

RRIM - Reinforced Reaction Injection Molding Technology

Firstly a feasibility study is required to define raw material shrinkage and flow.

Then mold in aluminum or steel is produced, with all the necessary movements to assure the component de-molding.

After production, it is possible to use cooling shell in resin or aluminum to cool down the component avoiding deformations. Afterwards, gluing and trimming stations are used to finish the product.

Thermo-set Technology

This technology implies raw material made with thermo-set resins, which reacts to the high temperature of the mold thus shaping the geometry of the component.

Usually the covering material is applied in a second step of the process.

Thermoforming Technology

In the initial phase of the process, raw material is heated up.

Further on, it is formed, covered and cut in a one-step process, in a water-cooled mold.